Injection

Injection kuumbwa (injection kuumba muUSA) igadziro rekugadzira rekugadzira zvikamu nekupinza zvinhu mudura. Iningion Kuumba kunogona kuitwa nehuwandu hwezvinhu, kusanganisira simbi, (iyo (iyo process yacho inonzi diecasting), magirazi, elastomers, confection, uye inowanzoitwa thermoplastic uye thermosetting polymers. Chidimbu chechikamu chinodirwa muhari inopisa, chakasanganiswa, uye chakamanikidzwa muvhu, umo chinotonhorera uye kuomesa kugadzirwa kwemukati. Mushure mekunge chigadzirwa chakagadzirwa, kazhinji chakagadzirwa nemaindasitiri kugadzira kana injiniya, Kuumbwa kunoitwa nemugadziri (kana kugadzira maturusi) kubva pasimbi, kazhinji ingava simbi kana aruminiyamu, uye yakanyatsogadzirwa-kugadzirwa kuumba maficha echikamu chaunoda. Jekiseni Kuumbwa kunoshandiswa zvakanyanya mukugadzira akasiyana siyana mativi, kubva padiki zvidimbu kusvika kune ese muviri mapaneru emota. Kufambira mberi mu 3D kudhinda tekinoroji, uchishandisa photopolymers iyo isinganyungudike panguva yejekiseni kuumbwa kweimwe yakadzika tembiricha thermoplastics, inogona kushandiswa kune mamwe akareruka majekiseni mafomu.

Zvikamu kuti dzive jekiseni rakaumbwa rinofanirwa kuve rakanyatsogadzirirwa kugadzirwa kuti iite basa rekuumba; izvo zvinoshandiswa pachikamu, chimiro chinodiwa uye chimiro chechikamu, izvo zvemukati zvekuumba, uye zvinhu zvemuchina wekuumba zvinofanirwa kutorwa zvese. Izvo zvinoshanda zvakasiyana-siyana zvekugadzira jekiseni zvinogoneseredzwa nehupamhi hwokufunga nezvekugadzira uye zvinogona kuitika.

Applications

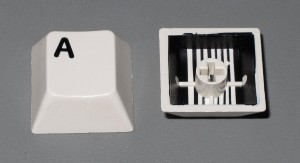

Inningion kuumba inoshandiswa kugadzira zvinhu zvakawanda zvakaita seaya waya. kavha, mabhodhoro emabhodhoro, emotokari zvikamu uye zvikamu, Gameboys, muhomwe combs, zvimwe zviridzwa zvemimhanzi (uye zvikamu zvawo), zvigaro-chimwe-zvigaro nematafura madiki, midziyo yekuchengetedza, zvikamu zvemishini (kusanganisira magiya), uye zvimwe zvigadzirwa zvepurasitiki zvakawanda zviripo nhasi. Inningion kuumba ndiyo inonyanya kuzivikanwa nzira yemazuva ano yekugadzira epurasitiki zvikamu; iyo yakanaka yekugadzira yakakwira yakawanda yeiyo chinhu chakafanana.

Maitiro ehunhu

Inningion kuumba inoshandisa gondohwe kana banga-mhando plunger kumanikidza yakanyungudika chikweshe zvinhu muforoma mhango; izvi zvinomira kuita chimiro chakateerana nemukaka weforoma. Iyo inowanzo shandiswa kugadzirisa ese ari thermoplastic uye thermosetting ma polymers, iine vhoriyamu inoshandiswa kune yekutanga kuve yakanyanya kukwirira. Thermoplastics yakapararira nekuda kwehunhu hunoita kuti ive yakanyatsokodzera jekiseni kuumbwa, senge kusununguka kwavanogona kuchinjiswazve, kuita kwavo kwakasiyana siyana kuchivabvumira kuti vashandiswe mumhando dzakasiyana siyana dzekushandisa, uye kugona kwavo kupfavisa uye kuyerera pakupisa. Thermoplastics zvakare ine chinhu chekuchengetedza pamusoro pemashemoseti; kana iyo thermosetting polymer isina kuburitswa kubva kujekiseni dhiramu nenzira inokodzera, kemikari crosslinking inogona kuitika ichikonzera sikuru uye kutarisa mavharuvhu kuti atore uye anogona kukuvadza jekiseni kuumbwa muchina.

Jekiseni Kuumbwa ine yakakwira yekumanikidza jekiseni rezvinhu zvakasvibirira kuita muforoma iyo inoumba iyo polymer muchimiro chaunoda. Mould dzinogona kuve dzeimwe mhango kana dzakawanda mhango. Mune akawanda mhango inoumba, yega yega mhango inogona kufanana uye inoumba iwo mamwe mativi kana inogona kuve yakasarudzika uye inogadzira akawanda akasiyana mageometri panguva imwechete kutenderera. Ma Molds anowanzo gadzirwa kubva kumaturu ezvishandiso, asi simbi dzesimbi uye maaluminium akakodzera kune zvimwe zvinoshandiswa. Aluminium molds kazhinji haina kukodzera kugadzirwa kwakanyanya vhoriyamu kana zvikamu zvine zvidimbu zvakaenzana kushivirira, sezvo zvine yakaderera michina zvivakwa uye vanowanzo tenderera kupfeka, kukuvara, uye deformation panguva yejekiseni uye yekunamatira matunhu; zvisinei, aruminiyamu anoumba anodhura-anoshanda mune yakaderera-vhoriyamu kunyorera, sezvo chakuumba nhema mari uye nguva zvakati kuderedzwa. Mazhinji maumburu esimbi akagadzirirwa kugadzirisa zvakanaka zvinopfuura miriyoni zvikamu mukati mehupenyu hwavo uye zvinogona kuita mazana ezviuru zvemadhora ekugadzira.

apo thermoplastics dzinoumbwa, kazhinji dzakapetwa mbishi zvinhu zvinodyiswa kuburikidza ne hopper kuita inopisa moto mudende ine yekudzosera sikuruu. Pamusuwo wedhiramu tembiricha inowedzera uye masimba eVan der Waals anorwisa kuyerera kwecheni kweumwe neumwe kuneta nekuda kwenzvimbo yakawedzera pakati pemamorekuru kune yakanyanya kupisa simba nyika. Maitiro aya anoderedza viscosity yayo, iyo inogonesa iyo polymer kuyerera neicho chinotyaira cheiyo jekiseni unit. Iyo sikuruu inonunura iyo mbishi mbichana kumberi, inosanganisa uye homogenize iyo inopisa uye viscous kugoverwa kwepolymer, uye inoderedza inodikanwa yekupisa nguva nekugadzira mashandiro acho uye nekuwedzera huwandu hwakakura hwekupesana kupisa kune iyo polymer. Izvo zvinhu zvinodyisa kumberi kuburikidza nevhavha yekutarisa uye zvinounganidza kumberi kwesikuru kuita vhoriyamu inozivikanwa se bara. Pfuti ivhoriyamu yezvinhu zvinoshandiswa kuzadza chakuvhuvhu, kubhadhara shrinkage, uye kupa kamuki (ingangoita gumi muzana yehuwandu hwekupfura vhoriyamu, iyo inosara iri mudhiramu uye inodzivirira iyo screw kubva pakubuda kunze) kuendesa kumanikidza. kubva sikuruu kune chakuvhuvhu mhango. Kana zvakakwana zvinhu zvaunganidzwa, izvo zvinhu zvinomanikidzwa kune yakanyanya kumanikidza uye velocity muchikamu ichigadzira mhango. Kudzivirira spikes mukumanikidza, maitiro acho anowanzo shandisa chinzvimbo chekuchinjisa chinoenderana ne10-95% yakazara mhango uko sikuruu inoshanduka kubva kune velocity yenguva dzose kuenda kune inogara ichimanikidza kudzora. Kazhinji jekiseni nguva dziri pasi pe98 sekondi. Kana iyo sikuru yasvika pachinzvimbo chekuchinjisa kumanikidza kurongedza kunoiswa, iyo inopedzisa kuzadza kweforoma uye inobhadharisa kupisa kwekushisa, iyo yakanyanya kukwirisa kune thermoplastics inoenderana nezvimwe zvakawanda zvinhu. Iko kumanikidza kurongedza kunoitwa kudzamara suwo (mhango yekupinda) ichisimbiswa. Nekuda kwehukuru hwayo hudiki, iro gedhi rinowanzo kuve nzvimbo yekutanga kusimbisa kuburikidza nehuremu hwayo hwese. Kana gedhi rangoomarara, hapasisina chinhu chinokwanisa kupinda mudumbu; Naizvozvo, sikuruwa inodzosera uye inowana zvinhu zveiyo inotevera kutenderera ukuwo zvinhu zviri mukati meforoma zvichitonhorera kuitira kuti ibudiswe uye igadzike zvine mutsigo. Iyi nguva yekutonhora inoderedzwa zvinoshamisa nekushandiswa kwemitsetse inotonhora inotenderera mvura kana mafuta kubva kune wekunze tembiricha controller. Kana tembiricha inodikanwa yawanikwa, chakuvhe chinovhura uye hoko yemapini, maoko, zvipambi, nezvimwe zvinofambiswa kumberi kuti zvinyangadze chinyorwa. Ipapo, chakuvhe chinovhara uye maitiro acho anodzokororwa.

Kune thermosets, kazhinji zvikamu zviviri zvakasiyana zvemakemikari zvinopinda mukati mebhara. Izvi zvikamu zvinobva zvatanga kudzokedzana nekushanduka kwemakemikari izvo zvinopedzisira zvogadzirisa zvinyorwa mune imwechete yakabatana network yemamolekyu. Sezvo maitiro emakemikari anoitika, izvo zviviri zvimvura zvinochinja zvachose kuita viscoelastic solid. Solidification mujekiseni dhiramu uye sikuruwa kunogona kunetsa uye kuve nemhedzisiro yemari; Naizvozvo, kurerutsa iyo thermoset kupora mukati meguruva kwakakosha. Izvi zvinowanzoreva kuti nguva yekugara uye tembiricha yemakemikari epamberi anoderedzwa mujekiseni. Iyo yekugara nguva inogona kudzikiswa nekudzikisa iyo dhiramu revhoriyamu kugona uye nekuwedzera iyo kutenderera nguva. Izvi zvinhu zvakakonzera kushandiswa kweyakaganhurirwa mukati, inotonhorera jekiseni unit inobaya iyo inogadzirisa makemikari mune inopisa inopisa yoga inopisa, iyo inowedzera mwero wekuchinja kwemakemikari uye inoguma munguva ipfupi inodiwa kuti uwane yakasimbiswa thermoset chinhu. Mushure mekunge chikamu chasimbiswa, mavhavha ari padhuze nekuparadzanisa jekiseni system uye makemikari ekutanga, uye chakuvhe chinovhura kubvisa zvikamu zvakaumbwa. Ipapo, chakuvhe chinovhara uye maitiro acho anodzokorora.

Nzvimbo dzisati dzaumbwa kana dzakagadzirirwa kugadzirwa dzinogona kuiswa mukati mechikosvo ichiumbwa chakavhurika, zvichibvumira kuti zvinhu zvakaiswa mukwende rinotevera riumbike uye kusimbisa zvakapoteredza ivo. Maitiro aya anozivikanwa se Isa kuumba uye inobvumira mitezo imwechete kuti igove nemidziyo yakawanda. Maitiro aya anowanzo shandiswa kugadzira mapurasitiki zvikamu zvine protruding simbi screws, achiitendera kuti isimbiswe uye isasimbiswa kakawanda. Iyi nzira inogona kushandisirwa In-mold mavara uye mafirimu lids inogona zvakare kubatanidzwa mumidziyo yepurasitiki yakaumbwa.

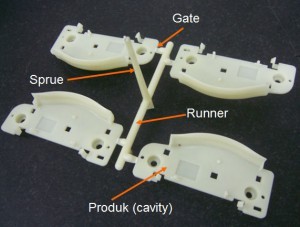

Mutsara wekuparadzanisa, sprue, magedhi mamaki, uye ejector pini mamaki anowanzo kuve aripo pachikamu chekupedzisira. Hapana chimwe chezvinhu izvi chinowanzodiwa, asi chisingadziviriki nekuda kwechimiro cheichi chiitiko. Mateki egedhi anoitika pagedhi iro rinobatanidza melt-dhiraivha nzira (sprue uye mumhanyi) kuchikamu chinogadzira mhango. Kupatsanura mutsetse uye ejector pini mamaki zvinokonzerwa nekukanganisa kweminiti, kupfeka, gasious vents, mvumo yezvikamu zviri padhuze mukufamba kwehukama, uye / kana kuenzana kwematanho kwenzvimbo dzekubata dzinosangana neyakajowa polymer. Dimensional misiyano inogona kuverengerwa kune isiri-yunifomu, kumanikidza-kunokanganisa deformation panguva yejekiseni, machining tolerances, uye isiri-yunifomu yekuwedzera kupisa uye kudzvinyirira kweforoma zvinhu, izvo zvinosangana nekukurumidza kuchovha bhasikoro panguva yejekiseni, kurongedza, kutonhora, uye ejection zvikamu zveichi chiitiko. . Zvinhu zveMold zvinowanzo gadzirwa nezvinhu zve coefficients dzakasiyana dzekuwedzera kwekushisa. Izvi zvinhu hazvigone kuverengerwa panguva imwe chete pasina kuwedzera kweyeredzi mumutengo wekugadzira, kunyepa, kugadzirisa, uye kuongorora kwehunhu. Iyo hunyanzvi muforoma uye chikamu dhizaini inoisa izvi zvinokanganisa nzvimbo munzvimbo dzakavanzika kana zvichikwanisika.

History

Muvambi weAmerica John Wesley Hyatt pamwechete nemunin'ina wake Isaiah, Hyatt patenteni muchina wekutanga wekujekesa jekiseni muna 1872. Muchina uyu waive wakareruka uchienzaniswa nemuchina urikushandiswa nhasi: waishanda senge tsono hombe yehodermic, ichishandisa pomba kuisa jekiseni repurasitiki kuburikidza nekupisa. humburumbira muforoma. Iyo indasitiri yakafambira mberi zvishoma nezvishoma pamusoro pemakore, ichiburitsa zvigadzirwa senge kora kugara, mabhatani, uye mizinga yebvudzi.

Vanachiremba veGerman Arthur Eichengrün naTheodore Becker vakagadzira mafomu ekutanga emunyoro we cellulose acetate muna 1903, yaive isinganyanye kupisa kupfuura cellulose nitrate. Yakazopedzisira yave kuwanikwa mune yefurawa fomu kubva kwaive nyore jekiseni kuumbwa. Arthur Eichengrün akagadzira muchina wekutanga wekugadzira jekiseni muna1919. Muna 1939, Arthur Eichengrün akabata pateraini yekuumbwa kwepurasitiki cellulose acetate.

Iyo indasitiri yakawedzera nekukurumidza muma1940 nekuti Hondo Yenyika II yakagadzira kudiwa kukuru kwezvinhu zvisingadhuri, zvakagadzirwa nevazhinji. Muna 1946, muAmerican mugadziri anonzi James Watson Hendry akagadzira yekutanga jekiseni jekiseni, iro rakatendera zvakadzama kutonga nekukurumidza kwejekiseni uye hunhu hwezvinyorwa zvakagadzirwa. Muchina uyu zvakare waibvumira kuti zvinhu zvisanganiswe zvisati zvaitika, kuti mapurasitiki ane mavara kana akaiswazve awedzerwe nemhandara uye osanganiswa zvakakwana asati aiswa jekiseni. Nhasi screw jekiseni michina account yehuwandu hwakawanda hwese majekiseni ejekiseni. Muma1970s, Hendry akaenderera mberi kugadzira jekiseni rekutanga-rakabatsirwa jekiseni rekuumba, iro rakabvumira kugadzirwa kwezvinhu zvakaoma kunzwisisa, zvakabikwa zvakapora nekukurumidza. Izvi zvakavandudza kwazvo kugadzirwa kwekushandurwa pamwe nesimba uye kupedzisa kwezvakagadzirwa zvikamu zvichideredza nguva yekugadzira, mutengo, uremu uye marara.

Iyo indasitiri yekuumba sindano yepurasitiki yakashanduka makore apfuura kubva mukugadzira makomiki uye mabhatani kuenda kugadzira zvigadzirwa zvakawanda zvevazhinji maindasitiri zvinosanganisira mota, zvekurapa, mhepo yemagetsi, zvigadzirwa zvevatengi, matoyi, kupomba, kurongedza, uye kuvaka.

Mienzaniso yemapuru inonyatsokodzera maitiro acho

Mapolymers mazhinji, dzimwe nguva anonzi masinese, anogona kushandiswa, kusanganisira ese thermoplastics, mamwe ma thermosets, uye mamwe ma elastomers. Kubva 1995, huwandu hwenhu huripo hwekushandisa jekiseni kuumbwa hwakawedzera pamwero we750 pagore; paive nezvinhu zvingangosvika zviuru gumi nezvisere zvaiwanikwa pakatanga izvozvo. Zvigadzirwa zviripo zvinosanganisira alloys kana musanganiswa wezvakambogadzirwa zvigadzirwa, saka vagadziri vezvigadzirwa vanogona kusarudza zvinyorwa neyeti yepamusoro yezvivakwa kubva mukusarudzwa kwakakura. Yakakura miitiro yekusarudzwa kwechinhu isimba uye basa rinodiwa kune chikamu chekupedzisira, pamwe nemutengo, asi zvakare chinyorwa chimwe nechimwe chine maparamendi akasiyana ekuumba iwo anofanirwa kuverengerwa. Zvakajairika ma polymers senge epoxy uye phenolic mienzaniso ye thermosetting mapurasitiki nepo nylon, polyethylene, uye polystyrene vari thermoplastic. Kusvikira zvichienzaniswa nguva pfupi yadarika, zvitubu zvepurasitiki zvaisakwanisika, asi kufambira mberi muzvinhu zvepolymer kunovaita izvozvi kuti zviite. Zvishandiso zvinosanganisira mabhureki ekusimbisa uye kudimbura kwekunze-zvishandiso webhu.

midziyo

Jekiseni Kuumbwa michina ine yezvinhu hopper, jekiseni gondohwe kana sikuruwa-mhando plunger, uye kudziyisa unit. Ichizivikanwawo semadhindaini, iwo anobata iyo maumbirwo ayo maumbirwo akaumbwa. Michina yekudhindisa yakaverengerwa nematani, ayo anoratidza huwandu hwesimba rekuomesa iro muchina unogona kushandisa. Iri simba rinochengeta muforoma yakavharwa panguva yejekiseni. Tonnage inogona kusiyana kubva pasi pemakumi mashanu ematani kusvika pamusoro pe5 matani, iine manhamba epamusoro anoshandiswa mune mashoma mashandiro ekugadzira. Iko kusunganidzwa kwesimba kunodiwa kunoonekwa nenzvimbo inofungidzirwa yechikamu chiri kuumbwa. Iyi nzvimbo inofungidzirwa inowedzerwa nechisimba simba kubva pa9,000 kusvika ku1.8 matani pasentimita imwe neimwe yenzvimbo dzakafungidzirwa. Semutemo wechigumwe, mana kana mashanu matani / mukati2 inogona kushandiswa kune zvakawanda zvigadzirwa. Kana iyo epurasitiki zvinhu yakaoma kwazvo, zvinoda imwe jekiseni kumanikidza kuzadza chakuvhuvhu, uye nekudaro zvimwe kiramba tonnage yekubata chakuvhe chakavharwa. Simba rinodiwa rinogonawo kugadziriswa nezvinhu zvakashandiswa uye kukura kwechikamu; hombe zvikamu zvinoda yakakwira clamping simba.

Mold

Mold or ari ndiwo mazwi akajairika anoshandiswa kutsanangura chishandiso chinoshandiswa kuburitsa mapurasitiki mukuumbwa.

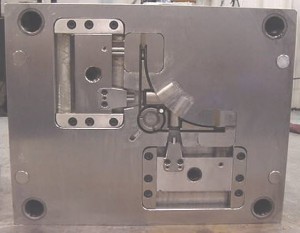

Sezvo maforoma anga achidhura kugadzira, aigara achingoshandiswa mukugadzira kwakawanda uko zviuru zvezvikamu zvaigadzirwa. Zvakajairika zvivakwa zvinovakwa kubva kune yakaoma simbi, pre-yakaoma simbi, aluminium, uye / kana beryllium-mhangura chiwanikwa. Sarudzo yezvinhu zvekuvaka fosi kubva kune inonyanya kukosha kwehupfumi. kazhinji, simbi kuumbwa kunodhura zvakanyanya kuvaka, asi hupenyu hwavo hwakareba hunogadzirisa yakakwira yekutanga mutengo pamusoro pehuwandu hwezvikamu zvakagadzirwa usati wasakara. Pre-akaomeswa simbi mafuru haashome kupfeka nemishonga uye anoshandiswa yakaderera vhoriyamu zvinodiwa kana hombe zvikamu. yavo chaiyo simbi kuomarara ndeye 38-45 pachiyero cheRockwell-C. Yakaomeswa simbi kuumbwa kurapwa kunopisa mushure mekugadzira. izvi zvakakwirira zvakanyanya maererano nekupfeka kuramba uye nehupenyu. Kuomarara kwakajairika kuri pakati pe50 ne60 Rockwell-C (HRC). Aluminium molds inogona kudhura zvakati wandei, uye kana yakagadzirirwa uye kugadzirwa nemidziyo yemazuva ano yemakomputa inogona kuve yakachengetedza kuumba makumi kana kunyangwe mazana ezviuru zvezvikamu. Beryllium mhangura inoshandiswa munzvimbo dzeforoma dzinoda kubviswa kwekupisa nekukurumidza kana nzvimbo dzinoona kupisa kwese kwese kuchigadzirwa. Izvo zvinogadzira zvinogona kugadzirwa neiyo CNC machining kana kushandisa magetsi kudzima machining maitiro.

Mold design

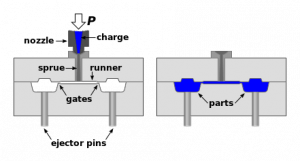

Iyo furu ine zvikamu zviviri zvekutanga, jekiseni mold (A ndiro) uye ejector mold (B ndiro). Izvi zvikamu zvinonzi zvakare se moulder uye muumbi. Plastiki resin inopinda muchimiro kuburikidza ne sprue or suo mune jekiseni mold; iyo sprue bushing ndeyekuisa chisungo zvakasimba pakatarisana nemhepo yemukati mejekiseni yemuchina wekuumba uye kubvumidza ipurasitiki yakanyungudika kuyerera kubva kubhari kupinda muchikuva, inozivikanwawo se cavity. Iyo sprue bushing inotungamira iyo yakanyungudutswa plastiki kune iyo cavity mifananidzo kuburikidza nematanho ayo akagadzirwa mukati mezviso zveA uye B maplate. Iyi migero inobvumira mapurasitiki kuti amhanye pamwe navo, saka ivo vanonzi sevanomhanya. Iyo plastiki yakanyungudika inoyerera kuburikidza nemumhanyi uye inopinda mune rimwe kana anopfuura magedhi akasarudzika uye mukati meiyo geometry yemukati kugadzira chikamu chinodiwa.

Huwandu hweresini inodiwa kuzadza sprue, mumhanyi uye maburi eforoma ane "bara". Mhepo yakavharirwa muforoma inogona kutiza kuburikidza nemhepo inovhuvhuta inoiswa pasi mumutsetse wekupatsanura weforoma, kana kutenderedza mapini ejector nemasiraidhi ayo ari madiki zvishoma pane maburi anochengeta iwo. Kana mweya wakasungwa ukasatenderwa kupukunyuka, unomanikidzwa nechisimba chezvinhu zvinouya uye wakasvinwa mumakona eiyo mhango, uko kunodzivirira kuzadza uye kunogona kukonzera kumwe kukanganisa. Mhepo inogona kutomanikidzika zvekuti inobatidza uye kupisa iyo yepurasitiki zvinhu zvakapoteredzwa.

Kuti ubvumire kubviswa kweiyo chikamu chakaumbwa kubva kuumbwa, izvo zvinoumba chimiro hazvifanirwe kupfuudza mumwe munzira iyo iyo iyo fungus inovhura, kunze kwekunge zvikamu zvekuumbwa zvakagadzirirwa kusimuka kubva pakati peiyo tsvina kana iyo furu ivhura (uchishandisa zvikamu zvinonzi Lifters .

Mativi echikamu chinoita senge achienderana nedemo rekudhirowa (axis yenzvimbo yakacheneswa (gomba) kana kuisirwa yakafanana nekumusoro nekudzika kwekufamba kweiyo furu painenge ichivhura nekuvhara) anowanzo angled zvishoma, anonzi dhizaini, kurerutsa kuburitswa kwechikamu kubva muforoma. Kukwana kusakwana kunogona kukonzera kushanduka kana kukuvara. Iyo dhizaini inodikanwa kuti isunungurwe kuburitsa inowanzoenderana nekudzika kwedumbu: iyo yakadzika mhango, iyo yakawanda dhizaini inodikanwa. Shrinkage inofanirwa zvakare kutariswa pakuona iro gwaro rinodiwa. Kana ganda racho rakatetepa, ipapo chikamu chakaumbwa chinowanzo dzikira pama cores anoumba achitonhorera uye kunamatira kune iwo ma cores, kana chikamu chacho chinogona kumonyoroka, kumonyoroka, kuputika kana kutsemuka kana mhango yabviswa.

Chiumbwa chinowanzo gadzirirwa kuitira kuti chikamu chakaumbwa chivimbike chinoramba chiri pane ejector (B) padivi peforoma kana ichivhura, uye inodhonza mumhanyi uye sprue kunze kwe (A) divi pamwe chete nezvikamu. Chikamu chinobva chadonha zvakasununguka kana chabviswa kubva ku (B) divi. Tunnel magedhi, anozivikanwawo seyepasi pegungwa kana eforoma magedhi, ari pazasi pemutsetse wekuparadzanisa kana chando chevhu. Kuvhura kwakagadzirwa mukati mechiso cheforoma pamutsetse wekuparadzanisa. Chikamu chakaumbwa chinotemwa (neforoma) kubva kumumhanyi system pane ejection kubva muforoma. Ejector pini, inozivikanwawo seyekugogodza mapini, ndiwo madenderedzwa mapini akaiswa mune chero hafu yeforoma (kazhinji iyo ejector hafu), iyo inosundira iyo yakapera yakaumbwa chigadzirwa, kana mumhanyi system kunze kweforoma. Iyo ejection yechinyorwa ichishandisa mapini, masaga, mitsetse, nezvimwe zvinogona kukonzera kusanzwisisika kana kukanganiswa, saka kutarisirwa kunofanirwa kutorwa kana uchigadzira iyo furu.

Iyo yakajairika nzira yekutonhora ichipfuura inotonhorera (kazhinji mvura) kuburikidza nehupamhi hwemakomba akadhirowewa kuburikidza nemahwendefa ekuumbwa uye akabatanidzwa nehoses kuti aumbe inoenderera nzira. Iyo inotonhorera inobata kupisa kubva muchimiro (icho chakatora kupisa kubva mupurasitiki inopisa) uye chengeta iyo furo panguva yekudziya chaiyo kuti isimbise ipurasitiki pamwero unonyanya kushanda.

Kuti uderedze kuchengetedza uye kufambisa, mweya nemakonzo zvakakamurwa kuita zvidimbu, zvinodaidzwa inowedzera, nemasangano madiki, anonziwo inowedzera, blocks, kana dzingisai zvidhinha. Nekutsiva zvinyorwa zvinoshandurwa, imwe furu inogona kuita mativi akasiyana echikamu chimwe chete.

Zvimwe zvikamu zvakaoma kunzwisisa zvinoumbwa uchishandisa zvimwe zvakaoma mapundu. Izvi zvinogona kuve nezvikamu zvinonzi slides, izvo zvinopinda mukati memukati me patendicular kune iyo dhiraidhi yekuraira, kuumba yakawedzera chikamu chechinhu. Kana iyo bhururu yavhurwa, masiraidhi anoburitswa kubva muchikamu chepurasitiki nekushandisa “mapini emakona” pane imwe stationary mold hafu. Iyi mapini inopinda mune slot mune masiraidhi uye anokonzeresa kuti masiraidhi afambe achidzokera kumashure kana imwe hafu yekufambisa ichivhurika. Chikamu chobva chakakwidzwa uye kuumbwa ndokuvhara. Iyo yekuvhara chiito chekuumbwa inokonzeresa kuti masiraidhi afambire mberi pamwe nepamakona emakona.

Mamwe mafuru anotendera izvo zvaimbove zvakaumbwa zvikamu kuti zvidzorerwazve kubvumidza ipurasitiki nyowani kuumbwa inotenderedza chikamu chekutanga. Izvi zvinowanzodaidzwa nekudarika. Iyi sistimu inogona kubvumira kugadzirwa kwemati-chidimbu matairi uye mavhiri.

Maviri-mapfuti kana akawanda-akapfura kuumbwa akagadzirirwa "kukurira" mukati mega kuumbwa kutenderera uye anofanirwa kugadziriswa pane akasarudzika jekiseni kuumbwa michina ine maviri kana anopfuura majekiseni majekiseni. Maitiro aya ari jekiseni kuumbwa maitiro anoitwa kaviri uye nekudaro ane mwero mudiki kwazvo wekukanganisa. Mudanho rekutanga, iwo ruvara rwepasi unogadzirwa kuita chimiro chakakosha, icho chine nzvimbo dzechipiri chekupfura. Zvino chinhu chechipiri, rumwe ruvara, jekiseni-rakaumbwa munzvimbo idzodzo. Pushbuttons nemakiyi, semuenzaniso, akagadzirwa nemaitiro aya ane mamaki asingagone kusakara, uye anoramba achiverengeka nekushandisa kwakanyanya.

Muforoma inogona kuburitsa makopi akati wandei ezvikamu zvakafanana mu "bara" rimwe chete. Huwandu hwe "zvimiro" muchimiro chechikamu ichocho zvinowanzo svitswa zvisizvo sekuvharirwa. Chishandiso chine fungidziro imwechete chinowanzozodaidzwa kuti imwechete fungidziro (mhango) muforoma. Furu ine maviri kana mazhinji emakonzo ezvikamu zvimwe chete izvozvo zvinganzi seyakawanda kufungidzira (cavity) kuumbwa. Mamwe akanyanya kugadzirwa vhoriyamu vhorumu mafuroni (senge ayo emabhodhoro bhokisi) anogona kuve anopfuura gumi nemakumi maviri nemaviri

Mune zvimwe zviitiko kuwanda kwecity cheni ichaumba akatevedzana ezvikamu zvakasiyana mudziyo imwecheteyo. Vamwe vanoita zvekugadzira vanodana aya maumbirwo emhuri kuumba sezvo zvese zvikamu zvine hukama. Enzaniso zvinosanganisira mapurasitiki emhando yekiti.

Mold kuchengetedza

Vagadziri vanoenda kune yakakura urefu kuti vadzivirire tsika kuumba nekuda kwemutengo wavo wepamusoro. Iyo yakakwana yekudziya uye humidity level inochengetwa kuti ive nechokwadi chehurefu hwakareba hwehupenyu kune yega yega chiumbwa mold. Mafomu masiko, akadai seaya anoshandiswa kugadzira jekiseni jekiseni kuumba, anochengetwa mukushisa uye humidity inodzora nharaunda kuchengetedza warping.

Zvigadzirwa zvematoni

Chishandiso chesimbi chinowanzo shandiswa. Simbi yakapfava, aluminium, nickel kana epoxy inokodzera chete prototype kana ipfupi kwazvo kugadzirwa kumhanya. Yemazuva ano yakaoma aluminium (7075 uye 2024 alloys) ine yakafanira mold dhizaini, inogona nyore kugadzira mafuru anokwanisa zviuru zana kana kupfuura chikamu chehupenyu pamwe neyakakodzera fekitori yekuchengetedza.

machine

Mhungu dzakavakirwa kuburikidza nenzira mbiri huru: standard machining uye EDM. Standard machining, mune yakajairika fomu, yakagara yakave nzira yekuvaka jekiseni mafuru. Nekuvandudzwa kwetekinoroji, CNC machining yakave nzira yekutanga yekuumba dzakaomesesa mapundu ane ruzivo rwakanyanya rwekuumbwa munguva shoma pane nzira dzekarese.

Iyo yemagetsi discharge machining (EDM) kana cheki kukonzera kuita yakashandiswa zvakanyanya mukugadzira kuumbwa. Zvimwewo nekubvumira kuumbwa kwechimiro chakaomesa muchina, iyo nzira inobvumidza pre-hardeneds mapepa kuti aumbwe kuitira kuti pasave nekupisa kupisa kunodiwa. Shanduko kune yakaomeswa kuumbwa nekujaira kuchera uye chigayo kazhinji zvinoda kusimudzira kuti inyorove, ichiteverwa nekupisa kurapa kuti iomese zvakare. EDM chiitiko chiri nyore umo maimodrode yakavezwa, inowanzogadzirwa nemhangura kana grafiti, inoderedzwa zvishoma nezvishoma pane iyo mold nzvimbo (pamusoro pemaawa akawanda), iyo inonyudzwa mumafuta eparafini (parafini). Simba rinoshandiswa pakati pechishandiswa uye fumbi rinokonzera kutsemuka kwemamiriro ekuumbwa mune inverse chimiro chekodhi.

mutengo

Kuwanda kwemabhuruku akabatanidzwa muvhu kunobatanidza zvakananga mumitengo yekuumba. Mashoma mashoma macustomer anoda mashoma asinganetsi ekushandisa basa, saka kudzikamisa huwandu hwemakonzo mukati-kutendeuka kunozoguma nekudzikisa kwekutanga mitengo yekugadzira kuti uvake jekiseni furu.

Sezvo huwandu hwemakomba hunotora chikamu chakakosha mukugadzirisa mutengo, ndizvo zvinoitawo kuomarara kwechikamu dhizaini. Kuomarara kunogona kuverengerwa muzvinhu zvakawanda senge yekupedzisa pamusoro, zvinoda kushivirira, zvemukati kana zvekunze tambo, tsananguro yakanaka kana huwandu hwezvikwiriso zvinogona kuverengerwa.

Zvimwezve zvinhu zvakaita sekubikwa kwemukati, kana chero chinhu chinokonzeresa kushandisira kuchawedzera mutengo wekuumbwa. Kumeso kupedzisa kweiyo musimboti uye cavity yezvikuumbwa zvichawedzera pesvedzera mutengo.

Rubber jekiseni rekuumba kuumba rinounza goho rakakura kwazvo pane zvigadzirwa zvisingagumi, zvichiita kuti ive inonyatsoita uye inodhura nzira yekuumba. Izvo zvinowanzoitika vulcanization maitiro anosanganisira chaiyo kudziya tembiricha kudzora anodzora marara ese marara.

Maitiro ekudzivirira

Nekuumbwa jekiseni, granular epurasitiki inodyiswa negondohwe rinosungirwa kubva muhipper mubhara rakatsva. Sezvo zvimedu zvinofamba zvishoma nezvishoma zvichienda mberi nehuremu-mhando plunger, ipurasitiki inomanikidzwa mukamuri inopisa, umo inonyungudika. Sezvo iye plunger inosimuka, iyo yakanyungudika epurasitiki inomanikidzwa kuburikidza nemhepo inoputika inopesana neiyo furu, ichiibvumira kuti ipinde muhombodo yekuvhara kuburikidza negedhi uye mumhanyi system. Iyo furu inoramba ichitonhora saka ipurasitiki inosimba kunge ingangoita kana iyo furu yazadzwa.

Injection kuumba kutenderera

Kuteedzana kwezviitiko panguva yejekiseni kuumbwa kwechikamu chepurasitiki chinonzi jekiseni rekuumba. Kutenderera kunotanga kana iyo bundu ichivhara, ichiteverwa nekukuvara kwepolymer mukati mevhu rekuumbwa. Kana chubhu ratozadzwa, kumanikidzwa kudzvanywa kuti kudzoreredze shrinkage yezvinhu. In inotevera danho, screw anotendeuka, kudyisa rinotevera kupfura kumberi screw. Izvi zvinokonzeresa kuti banga ridzokere shure sekupurwa kunotevera. Kana chikamu chanyatsokwana, kuumbwa kunovhurika uye chikamu chacho chinobva chakandwa.

Sayenzi inopesana neyakaumba tsika

Pachivanhu, jekiseni chikamu chekuumba kwacho chakaitwa kamwechete kumanikidzwa kuzadza uye kurongedza mhango. Iyi nzira, zvisinei, yakabvumidza mutsauko mukuru muhukuru kubva kutenderera-kuenda-kutenderera. Zvimwe zvinowanzo shandiswa ikozvino isainzi kana yakadonhedzwa kuumbwa, nzira yakapayirwa neRJG Inc. Mune izvi jekiseni repurasitiki "rakabvarurwa" muzvikamu kubvumira kudzora kuri nani kwezvikamu zvidimbu uye zvimwe kutenderera-kutenderera (kunowanzoidzwa kunzi kupfura-ku -shot muindasitiri) kuenderana. Kutanga iyo mhango inozadzwa kusvika ingangoita 98% izere uchishandisa velocity (kumhanya) kutonga. Kunyangwe iko kumanikidza kuchifanira kukwana kuti ubvumidze kumhanya kwaunoda, kumanikidza kwekumanikidza panguva ino hakudi. Kamwe iyo mhango inenge 98% izere, muchina unoshanduka kubva ku velocity kudzora kuenda kune yekumanikidza kudzora, uko iyo mhango "" yakarongedzwa kunze "pane inogara ichimanikidza, panodiwa velocity yakakwana yekusvitsa zvinodikanwa zvinodikanwa. Izvi zvinobvumira chikamu chemadhigiri kudzorwa kusvika mukati mezviuru zveasendimita kana zvirinani.

Mhando dzakasiyana dzejekiseni kuumba maitiro

Kunyangwe yakawanda majekiseni ekuumba maitiro akafukidzwa neakajairika maitiro ekutsanangurwa pamusoro, pane akati wandei akakosha kuumbwa kusiyanisa kusanganisira, asi isina kuganhurwa kune:

- Die Kudzingwa

- Metal jekiseni kukuumba

- Thin-wall jekiseni kuumba

- Injection kuumbwa kweyemvura silicone rubha

Rondedzero yakazara yakawanda yeanopinda jekiseni maitiro anogona kuwanikwa pano:

Kugadzirisa dambudziko

Kunge zvese maindasitiri maitiro, jekiseni kuumbwa kunogona kuburitsa akakanganisa zvikamu. Mundima yekubaya jekiseni, kugadzirisa dambudziko kunowanzoitwa nekutarisa nzvimbo dzakakanganisika nekuda kwehumwe urema uye kugadzirisa izvi zvirema nekuumbwa kweumbwa kana maitiro ehurongwa hwacho. Miedzo inowanzoitwa isati yazara kugadzirwa kumhanya mukuedza kufanotaura zvikanganiso uye kuona zvakaringana tsananguro dzekushandisa mukujekesa.

Kana uchizadza chakuvhe chitsva kana chisina kujairika kekutanga, uko kukura kwepfuti kweiyo furu kusingazivikanwe, nyanzvi / setter yekushandisa inogona kuita kuyedza kumhanya kusati kwazara kugadzirwa. Iye anotanga nekapfupi pfuti huremu uye anozadza zvishoma nezvishoma kusvikira chigayo chave 95 kusvika 99% chizere. Kana izvi zvangozadzikiswa, hushoma hwekubata kumanikidza kunozoiswa uye nguva yekubata yawedzera kusvikira suwo ratonhora (nguva yekusimbisa) yaitika. Gedhi kufefetera kubva panguva inogona kutemerwa nekuwedzera iyo inobata nguva, uyezve kuyera chikamu. Kana huremu hwechikamu husinga shanduke, zvinobva zvazivikanwa kuti gedhi rakagwamba uye hapana zvimwe zvinhu zvinojowa muchikamu. Gedhi rekusimbisa nguva rakakosha, sezvo ichitarisa nguva yekutenderera uye mhando uye kuenderana kwechigadzirwa, icho chaicho inyaya yakakosha mune zvehupfumi hwekugadzira maitiro. Kubata kumanikidza kunowedzerwa kudzamara zvikamu zvacho zvave zvisina masinki uye chikamu chehuremu chazadzikiswa.

Kuremara zvikanganiso

Inningion kuumba ndiyo yakaoma tekinoroji pamwe nematambudziko ekugadzira. Zvinogona kukonzerwa nehurema mumango, kana kazhinji kazhinji nekuumbwa kwacho pachako.

| Kuremara zvikanganiso | Rimwe zita | rondedzero | Zvinokonzera |

|---|---|---|---|

| mhoni | Kutuka | Yakakwidzwa kana yakatsemurwa zone pamusoro pechikamu | Turu kana kuti zvinhu zvakapisa zvakanyanya, zvinowanzokonzerwa nekushaiwa kwekutonhora zvakatenderedza pane chombo kana heater isina kunaka |

| Pisa mamakisi | Kupisa kwemhepo / kupisa gasi / kufira | Nzvimbo dzakasviba kana dzebrown dzakapisirwa pachikamu chinowanikwa panzvimbo dze furtist kubva kugedhi kana kune mweya wakasungwa | Tool inoshaya pakudonhedza, kumhanya kwejekiseni kwakanyanya |

| Colour streaks (US) | Ruvara mitsara (UK) | Localised shanduko yeruvara / ruvara | Masterbatch haisi kusanganisa mushe, kana izvo zvinhu zvapera uye iri kutanga kuuya kuburikidza neyechisikigo chete. Zvekare zvemavara zvinhu "kudhonza" mumuromo kana cheki vharuvhu. |

| Delamination | Thin mica kunge matombo akaumbwa mune chikamu madziro | Kusvibiswa kwezvinhu, semuenzaniso PP yakasanganiswa neABS, zvine njodzi zvakanyanya kana chikamu chikashandisirwa basa rekuchengetedza kuchengetedza sezvo zvinhu zvacho zvisine simba shoma kana zvatsveneswa sezvo zvigadzirwa zvisingakwanise kubatana. | |

| mbaravara | Bururu | Yakawandisa zvinhu mune yakatetepa inodarika yakajairwa chikamu geometry | Muto wakazara pamusoro kana wedhara mutsara pane chishandiso wakanganisika, yakawandisa jekiseni nekukurumidza / zvinhu zvakakuvara, simba rekumanikidza rakaderera. Inogonawo kukonzerwa nehutsvina uye zvakasvibiswa zvakatenderedza pekushandisa nzvimbo. |

| Yakabatanidzwa inosvibisa | Yakabatanidzwa | Zvekunze chidimbu (chakapiswa kana chimwewo) chakabatanidzwa muchikamu | Zvidimbu zviri padura rechishandiso, zvakasvibiswa kana zvakasvibirira tsvina mugoronga, kana kupisa kupisa kwakawanda kupisa zvinhu zvisati zvaitika jekiseni. |

| Maruva anoyerera | Inoyerera mitsara | Kunongedzera "off toni" wavy mitsara kana mapatani | In injion inomhanyisa kwazvo (ipurasitiki yakanyorovera pasi zvakanyanya panguva yekuita jekiseni, kumhanya kwejekiseni kunofanirwa kumiswa nekukurumidza sezvakakodzera kuita kwacho uye zvinhu zvinoshandiswa) |

| Gedhi Blush | Halo kana Blush Maka | Yakatenderedzwa pateni yakakomberedza gedhi, kazhinji inongori nyaya pane inopisa runner runokumbira | In injion kumhanya kwakanyanya kukurumidza, gedhi / sprue / mhanyisa saizi idiki kwazvo, kana iyo inonyungudika / dutu remhepo rakadzika kwazvo. |

| Jetting | Chikamu chinoshatiswa nekuyerera kwekufamba kwezvinhu. | Huru dhizaini dhizaini, chinzvimbo chinzvimbo kana mumhanyi. In injion kumhanya yakaiswa yakanyanya. Kusagadziriswa kwemasango ayo anokonzeresa kufa zvishoma uye kunoguma kwasira. | |

| Knit mitsara | Weld netambo | Mtsetse diki padivi pekushure kwepakati pini kana windows pane zvikamu zvinotaridzika semitsetse. | Inokonzerwa nekwanyunguduka-kumberi kuyerera kwakatenderedza chinhu chakamira chinodada mune chimwe chikamu chepurasitiki pamwe nekupedzisira kwekuzadza uko kunyauka-kumberi kunosangana zvakare. Inogona kuderedzwa kana kubviswa neyekuumbwa-kuyerera kudzidza kana iyo furu iri muchikamu chekugadzira. Kana chikango chaitwa uye gedhi rikaiswa, munhu anogona kudzora kukanganisa uku nekuchinja nyungudika uye tembiricha yekuumba. |

| Kudzvinyirira Polymer | Kuputika kwepolymer kubva kuhydrolysis, oxidation nezvimwe. | Mvura yakawandisa muma granules, kupisa kwakanyanya mubhari, kumhanya kwakawandisa kuchimisa kuchikonzera kupisa kwakakura kwazvo, zvinhu zvichitenderwa kugara mubhavhu kwenguva refu kwazvo, kuwandisa zvakanyanya kuri kushandiswa. | |

| Sink mavara | [inonyura] | Kusuwa kwenzvimbo (Munzvimbo dzakawandisa) | Kubata nguva / kudzvinyirira yakaderera, nguva inotonhora ipfupi, nevaputi vasina kupisa mamhanyi izvi zvinogona kukonzerwazve nekupisa kwegedhi kuiswa yakanyanya kukwirira. Zvakawandisa zvinhu kana madziro akakora. |

| Pfupi | Isingazadze kana pfupi pfupa | Chikamu chidimbu | Kushaikwa kwezvinhu, kumhanya jekiseni kana kumanikidza zvakaderera, kuumbwa zvakanyanyisa, kushayikwa kwemagesi vents |

| Splay mavara | Splash chiratidzo kana sirivhi | Kazhinji inoratidzika senge sirivha mirukova pamwe inoyerera paseji, zvisinei zvichienderana nerudzi uye ruvara rwezvinhu izvo zvinogona kumiririra semabhuru madiki anokonzerwa nehunyoro hwakanyorova. | Mhute mune izvo zvinhu, kazhinji kana hygroscopic resin yaomeswa zvisizvo. Kubata gasi munzvimbo dze "rib" nekuda kwekuwedzeredza jekiseni velocity munzvimbo idzi. Zvinyorwa zvinopisa zvakanyanya, kana zviri kuveurwa zvakanyanya. |

| Kusimba | Tambo kana kuti refu-suwo | Tambo senge vasara kubva yapfuura pfuti yekufambisa mune nyowani | Tembiricha yemubhu yakanyanyisa kukwirira. Gedhi harina kuomeswa nechando, hapana kudzvinyirira kwesikuru, hapana kuzorora kwemashure, kuiswa kwakasarudzika kwemabhendi emota mukati mechishandiso. |

| Voids | Mukana nzvimbo mukati mechikamu (mweya muhomwe unowanzo shandiswa) | Kushaikwa kwekumanikidza (kubata kumanikidza kunoshandiswa kurongedza chikamu mukati menguva yekubata). Kuzadza nekukurumidza zvakanyanya, kusabvumira iwo mativi echikamu kuti amise. Zvakare mold inogona kunge iri kunze kwekunyoreswa (kana iwo mahafu maviri asingaise pakati zvakanaka uye chikamu madziro haasi iwo akafanana mukobvu). Ruzivo rwapihwa iko kunzwisisana kwakajairika, Kururamisa: Kushaiwa kwepaketi (kusabata) kumanikidza (kumanikidza kwepaki kunoshandiswa kurongedza kunze kunyangwe iri chikamu panguva yekubata). Kuzadza nekuchimbidza hakukonzere mamiriro aya, sezvo chisina chinhu isingi isina nzvimbo yekuitika. Mune mamwe mazwi, sezvo chikamu chinodzikira resini yakaparadzaniswa pachayo sezvo pakanga pasina resini yakakwana mudumbu. Iko kushaya kunogona kuitika chero munzvimbo kana chikamu hachikwaniswi neukobvu asi neiyo resin kuyerera uye kupisa kwemagetsi, asi zvinowanzoitika kunzvimbo dzakakora senge mbabvu kana mabhosi. Zvimwezve zvinokonzeresa void hazvinyungudike padziva rekunyungudika. | |

| Weld waya | Knit mutsara / mutsara weMeld / mutsara wekutamisa | Akadamburwa mutsetse apo miviri yekuyerera inosangana | Mould kana tembiricha yezvinhu inodzika yakadzika kwazvo (izvo zvinhu zvinotonhora kana zvasangana, saka hazvisunge). Nguva yekuchinja pakati pejekiseni uye kuchinjisa (kurongedza nekubata) yakanyanya kukurumidza. |

| Warping | Kutsigira | Chikamu chakatsauswa | Kutonhora kupfupisa, zvinhu zvakapisa, kushaya kutonhora kwakakomberedza chishandiso, mvura isiriyo tembiricha (izvo zvikamu zvinokotama mukati zvakananga kudivi rinopisa rechishandiso) Unneven kuderera pakati penzvimbo dzechikamu. |

Nzira dzakaita seyunivhesiti CT yekuongorora dzinogona kubatsira nekuwana izvi zvinokanganisa kunze uye mukati.

Kushivirira

Kuumbirira kushivirira ndiyo yakatenderwa kubvumirwa pane kutsauka mune ma parameter akadai mahuremu, masimbi, mapendero, kana makona, nezvimwe. Kuwedzera kudzora mukuisa kushivirira pane kazhinji pane kuderera uye kwakanyanya kugumira paukobvu, zvichienderana nemaitiro anoshandiswa. Jekiseni Kuumbwa kazhinji inokwanisa kutakura zvakaenzana neITI Giredhi ingangoita 9-14. Iko kushivirira kunokwanisika kweiyo thermoplastic kana iyo thermoset iri ± 0.200 kusvika ± 0.500 millimeter. Mune akakosha mashandisirwo ekushandisa kushivirira kwakaderera se ± 5 µm pane ese madhiri uye akaenzana maficha anowanikwa mukugadzira kwakawanda. Kumusoro kunopedzwa kwe0.0500 kusvika ku0.1000 µm kana zvirinani zvinogona kuwanikwa. Nzvimbo dzakashata kana dzine matombo dzinogona zvakare.

| Mhando yekuumba | Chaizvoizvo [mm] | Zvinogoneka [mm] |

|---|---|---|

| Thermoplastic | ± 0.500 | ± 0.200 |

| Thermoset | ± 0.500 | ± 0.200 |

Simba rinodiwa

Simba rinodikanwa pakuita uku kwekukuvara kwejekiseni zvinoenderana nezvinhu zvakawanda uye zvakasiyana pakati pezvinhu zvinoshandiswa. Kugadzira Maitiro Referensi Guru inotaura kuti zvinodiwa nemagetsi zvinoenderana ne “giravhiti yezvinhu, iyo nzvimbo inonyungudika, kudziyisa kwemafuta, chikamu chesayizi, uye chiyero chekuumba.” Pazasi petafura kubva papeji 243 yechinongedzo chakafanana sezvakambotaurwa izvo zvinonyatsoratidza hunhu hunoenderana nesimba rinodiwa pazvinhu zvinonyanya kushandiswa.

| zvinhu | Simba rakakashama | Melting point (° F) | Nhamba yakanyunguduka (° C) |

|---|---|---|---|

| Epoxy | 1.12 kuna 1.24 | 248 | 120 |

| phenolic | 1.34 kuna 1.95 | 248 | 120 |

| zvinhu zvenaironi zvinotora | 1.01 kuna 1.15 | 381 kuna 509 | 194 kuna 265 |

| Polyethylene | 0.91 kuna 0.965 | 230 kuna 243 | 110 kuna 117 |

| Polystyrene | 1.04 kuna 1.07 | 338 | 170 |

Robotic kuumba

Automation zvinoreva kuti kukura kudiki kwezvikamu kunobvumidza nhare yekuongorora system yekuongorora dzakawanda zvikamu nekukurumidza. Pamusoro pekukwirisa system dzekuongorora pane otomatiki michina, akawanda-axis marobhoti anogona kubvisa zvikamu kubva muhomba uye kumisikidza mamwe maitiro.

Zvimwe zviitiko zvinosanganisira kubvisa chikamu kubva kuumbwa nekukurumidza mushure mekunge zvikamu zvagadzirwa, pamwe nekushandisa michina yekuona michina. Robhoti inobata chikamu mushure mekunge mapini ejector awedzerwa kuti asunungure chikamu kubva mukuumbwa. Izvo zvinozozvifambisa kuti zviite munobata nzvimbo kana zvakananga kune yekuongorora system. Iyo sarudzo inoenderana nemhando yechigadzirwa, pamwe neyakajairwa zvigadzirwa zvekugadzira. Maonero ehurongwa hwakaiswa pamarobhoti hwakavandudza zvakanyanya hutongi hwekuisa yezvikamu zvakaumbwa. Robhoti inofambisa inokwanisa kunyatso kuona kuiswa kwechinhu chesimbi, uye kuongorora nekukurumidza kupfuura zvinoita munhu.